The subject of packaging waste has received significant social and political focus in the last few years. Due to the growing awareness of sustainability, the issue of packaging waste has become one of the most important challenges for companies.

In Germany, the scale of the problem is particularly dramatic: with 19 million tons of packaging used annually, the urgent need for an efficient and effective solution is becoming increasingly clear. This is not just an ecological and moral issue. Consumers themselves are becoming more and more concerned and alarmed by the flood of packaging waste. According to a study, 45% of consumers feel significantly disturbed by packaging waste and more than a quarter of respondents even stop buying products that, in their opinion, generate too much packaging waste.

There is a clear consensus here: consumers see manufacturers as having a duty to reduce this waste. Almost half of all consumers, 45%, consider the producers of the goods to be primarily responsible for reducing packaging waste.

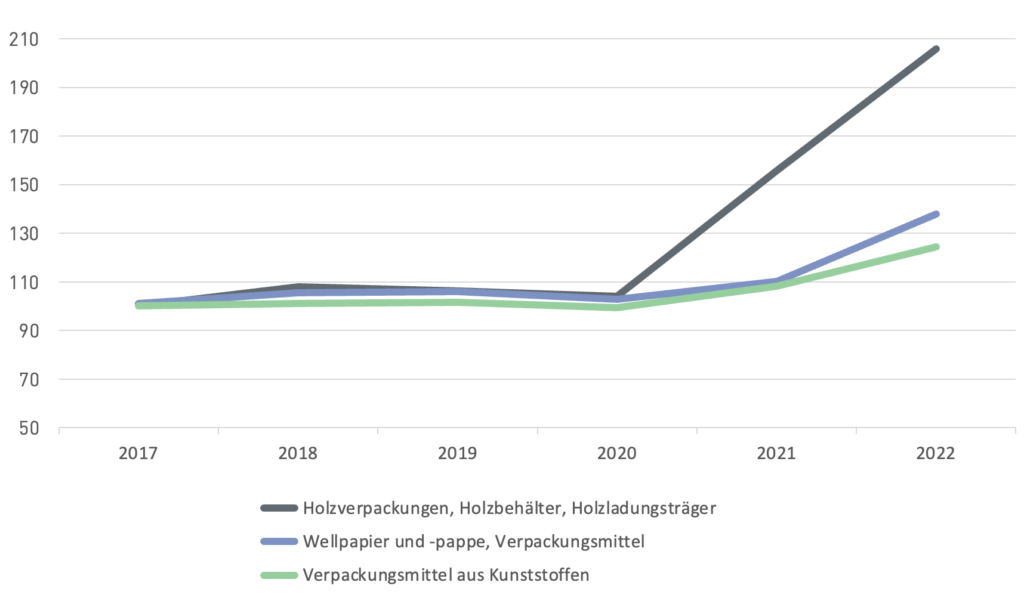

However, it is not just a question of environmental protection. The economic demands and pressures are also increasing. From 2020 to 2022, the producer price index for wood packaging has almost doubled. Prices for other packaging materials, such as corrugated board or plastic, have also increased significantly. These rising costs for packaging materials are forcing manufacturers to put current operations and processes to the test and. It is obvious that changes need to be made to current practices and strategies and that comprehensive optimization of processes is necessary.

Development of producer price index of packaging (DE)

Packaging optimization: an effective way to shape the future

In view of the growing challenges around packaging waste, packaging optimization from dmaic offers an efficient and effective solution. Our approach combines reduction of material consumption and efficient use of resources. By using modern technologies such as automation and 3D calculation, we maximize packaging utilization and minimize waste.

The advantages are many: costs for packaging and logistics are reduced, unnecessary waste is avoided, and transport damage is reduced through careful planning and appropriate surface treatment. Thanks to our approach of looking at each packaging process individually, we are flexible and can adapt to changing part combinations and lot sizes.

You can find more information about our diverse solutions here.

Sources: Genesis online database – 61241-0003 Federal Environmental Agency Statista survey on disposal behavior